Our Collection of

Prestil pre-pressed concrete pole distinguishes itself by:

The elasticity is determined by the particular compound and the choice of a high quality harmonic steel strand. Those are two of the factors that leads to a higher elasticity of Prestil pre-pressed concrete.

Whether it’s a vineyard plantation or an orchard plantation, the pole must also ensure a good strenght performance. Depending on the regions where they are located, vineyards may be exposed to strong winds and particularly intense atmospheric events, while in orchards there is the aggravating weight of snow or hail that drains on the net. These two aspects must be considered with great care and are crucial to ensure a stable and long-lasting system.

The Perfect trellising wire is easy to install, requires little maintenance and has a long service-life. Duron trellising wire combines the right features just to achieve that. The high strength, low elongation wire results in various advantages such as more usable wire length with the same final breaking load and a higher resilience that lasts many harvests. The advanced, zinc-aluminium coating Bezinal® 2000 exceeds the performance of heavy galvanised wires in both quality and lifetime. As a result, Duron trellising wires stay tight and corrosion-free during the entire lifespan of the vine.

A trellis support system relies on poles and wires to support the weight of the trees and fruit, including wind loads. Stroger poles installed at a greater depth create a stronger system. Not only is the post itself stronger but the lateral resistance to post overturning is higher because the forces acting on poles are distributed over a larger contact area. Increasing the post embedment in the soil will significantly increase the load capacity of the support system. The support system capacity is also dependant on the strength of the soil around the post.

The soil around driven poles will provide more resistance to wire and wind loads compared to a post installed in an auger borehole. Therefore, drive the poles where possible because a driven post can be 50% stronger than an augered poles.

The support poles are typically installed in a straight line. The poles at each end of the line (endpoles) will carry more load than the poles within the line of poles (line-poles). The end-poles are designed differently than the line-poles. The designs presented here consider a recommended standard for line-poles and different design options for the end-poles. The recommended post diameters presented in this manual refer to the minimum diameter of the post. For example, a 4” post can range up to 5” in diameter. The larger poles should always be selected and used for the end-poles.

| Diameter mm | Gauge of Wire | Length per Coil |

|---|---|---|

| 1.80 | 15 | 1600 |

| 2.00 | 14 | 1600 |

| 2.20 | 13 | 1600 |

| 2.50 | 12 | 1000 |

| 2.80 | 11 | 800 |

| 3.20 | 10 | 800 |

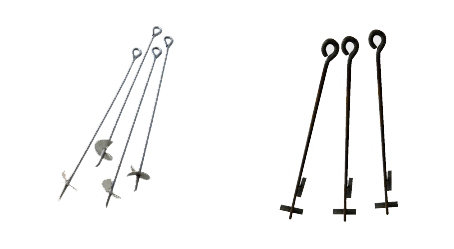

The general types of soil anchors can be used to secure tie-back wires/ropes. The helical steel plate welded onto the end of a steel rod. The anchor should be installed strong enough into the ground. Ideally, each soil anchor should be installed in firm undisturbed soil at an inclination such that the wire rope or anchor shank to points towards the tie-back attachment location on the end port. The attachment loop should be near the ground surface after the anchor is installed.

The general types of soil anchors can be used to secure tie-back wires/ropes. The helical steel plate welded onto the end of a steel rod. The anchor should be installed strong enough into the ground. Ideally, each soil anchor should be installed in firm undisturbed soil at an inclination such that the wire rope or anchor shank to points towards the tie-back attachment location on the end port. The attachment loop should be near the ground surface after the anchor is installed.

Welcome to Fruits Care Agro, where we put the “fruit” in fruitful! We are a leading service provider in fruit security, packaging, and commercial solutions. We offer the “berry” best value to our customers.